Explosion-Proof Climate Chamber for Testing Battery of Electric Car

New energy vehicle market is expanding rapidly, while the charging technology and cruising range have not been perfected. Recently, spontaneous combustion accidents of new energy vehicles have also become the focus of attention of users.

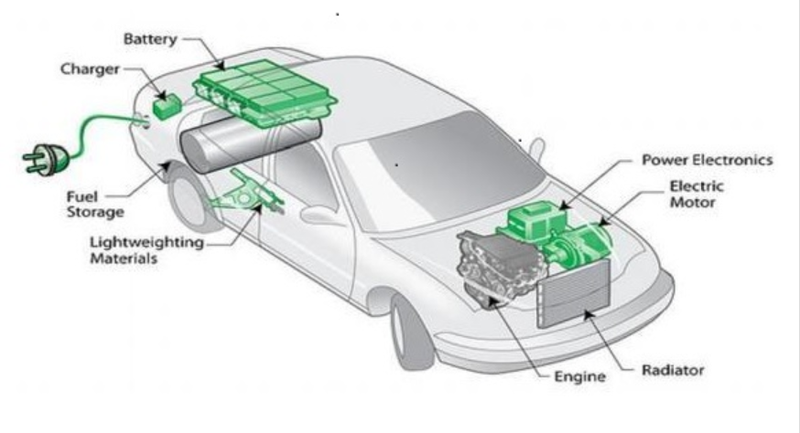

Power batteries are the core components and power sources of electric cars, so battery reliability testing is the key to the development of new energy vehicle industry. Labtech supplies Climate Chamber for reliability testing includes heat test, freeze test, thermal cycle test, damp heat test and so on.

What’s the working principle of heating and refrigeration system?

Climate Chamber is directly heated by nickel-chromium alloy electric heating wire. When doing heat test, circulating fan ventilates the air to generate convection and blow into inside chamber, so as to achieve the effect of heating the air inside chamber. Control system adopts microcomputer to control the conduction time of heating wire, the heating mass and loss reach a dynamic balance to achieve the purpose of precise temperature control.

The refrigeration system of Climate Chamber adopts French Tecumseh hermetic compressor, which applies energy adjustment technology to ensure the normal operation of refrigeration unit and effectively regulate the energy consumption and refrigeration capacity of refrigeration system. Using balance temperature adjustment (BTC), under the refrigeration system is continuously working, control system controls the output of heater through PID automatic calculation according to the set temperature, then achieves the dynamic balance.

What’s the special requirement of Climate Chamber tests battery cells?

1. When testing more than one battery cells, the interior chamber adopts horizontal air supply mode to ensure the uniform and stable of temperature and humidity inside climate chamber.

2. Chamber has cable ports on lateral side for battery cells to be powered, its number and size can be customized according to requirements.

3. Reinforced hinge and explosion-proof lock design, door hinge adopts reinforced 304 stainless steel.

4. There is explosion-proof pressure relief valve on lateral side, which automatically relieves pressure when the pressure is too high inside chamber.

5. Equipped with fire extinguishers to prevent unqualified batteries from explosion and fire.

6. Chamber has smoke sensor and smoke exhaust system.

7. Three-color sound and light warning lamp.