Reliability testing of solar cell modules (EVA films)

Proposal Introduction:

EVA plays a very important role in improving the power generation efficiency of solar cell modules, providing protection against environmental and climate changes, and ensuring the service life of solar module. EVA is non-adhesive and anti-adhesive at normal temperature. After holding pressure under certain conditions in the packaging process of solar cells, EVA will produce bonding and adhesive curing, which is a heat-curing thermal rescue film. The cured EVA film becomes completely transparent and has quite rich light transmittance. The cured EVA can withstand atmospheric changes and has elasticity. The solar cell chip is wrapped and bonded with the upper glass and the lower TPT by vacuum laminating technology.

Test purpose:

Confirm the weather fastness, light transmittance, bonding force, absorption deformation and ability to absorb physical impact of EVA, and damage rate in the pressing process

Test chambers:

HAST Highly Accelerated Stress Test Chamber, PCT Pressure Cooker Test Chamber, UV Weathering Test Chamber

Sample:

1. Glass/ EVA/ Wet paper/EVA/ Glass superimposing

2. Glass/ EVA/ Conducting copper / EVA/ Glass superimposing

EVA-UV testing:

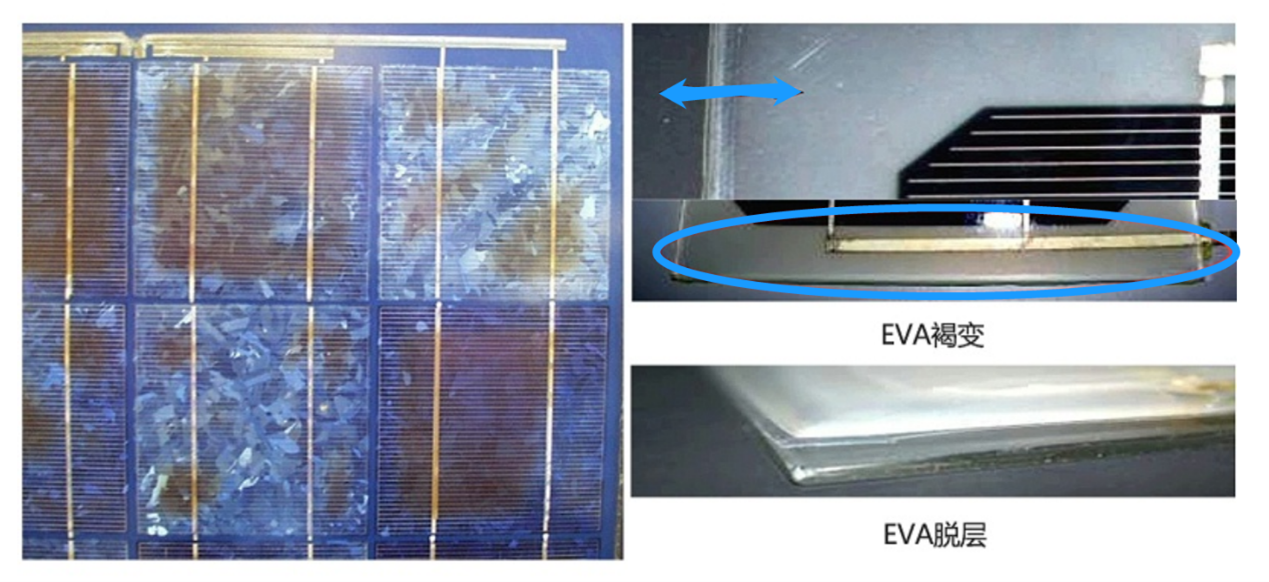

The ability of EVA to withstand ultraviolet (UV) irradiation is attenuated. After a long time of UV irradiation, EVA film will appear brown, penetration rate decreases and other problems.

Characteristic changes of EVA under humi-heat test: Discoloration, Atomization, Browning, Delamination

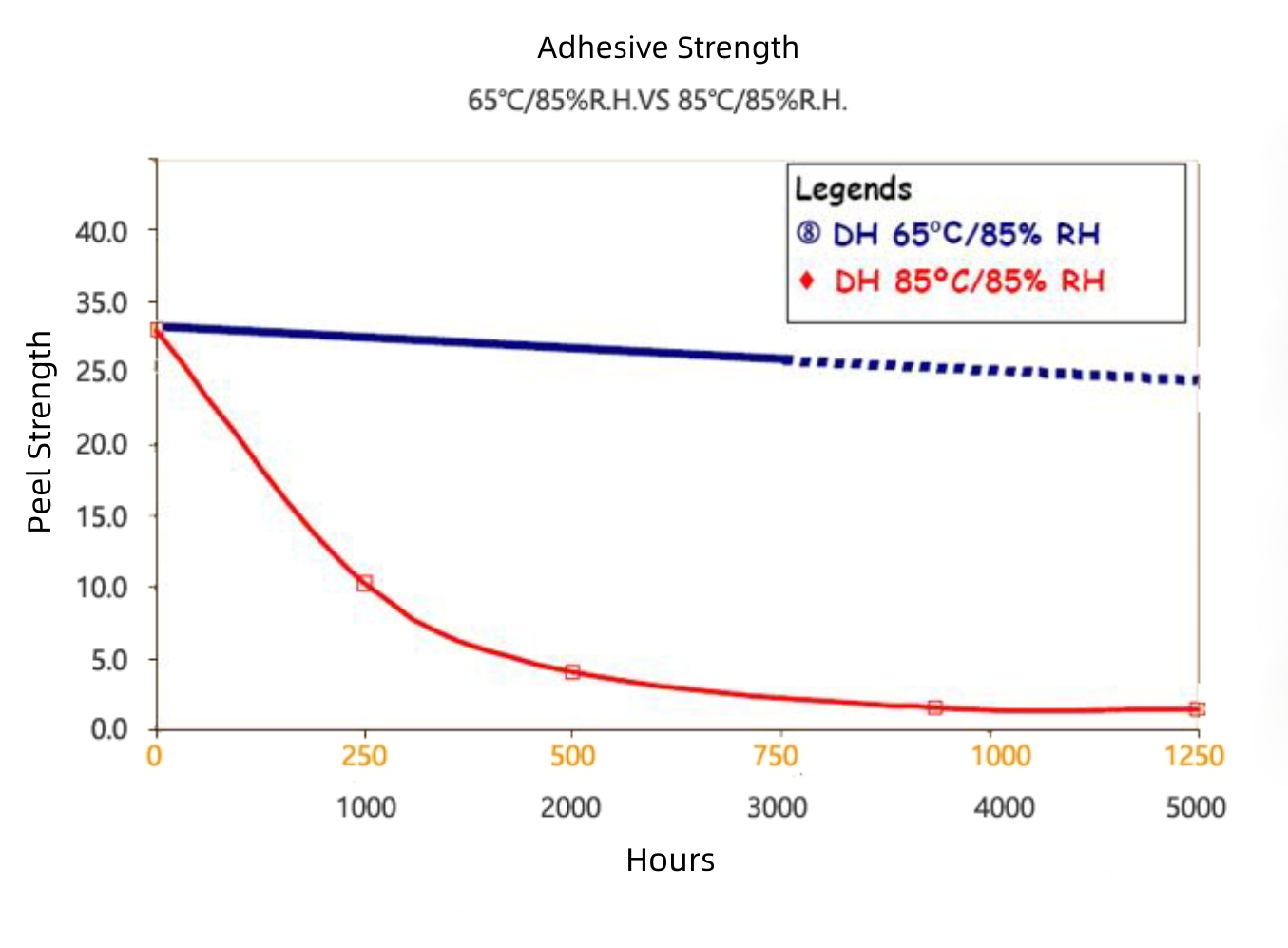

Comparison of bonding strength of EVA at high temperature & high humidity:

EVA film under 65C/85%RH and 85C/85%RH two different heat conditions testing to compare the degradation of the adhesion strength, found that after 5000hours testing under 65C/85%RH conditions, its degradation benefit not high, but EVA lost the viscosity quickly under 85C/85%RH test condition, there was a significant reduction in bond strength at 250 hours.

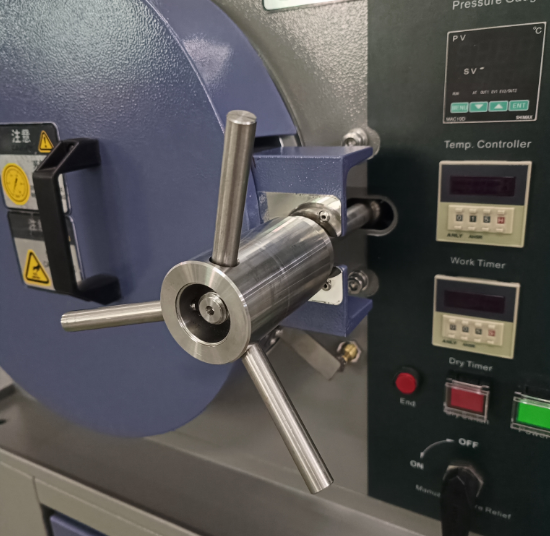

EVA - HAST Chamber

Objective: Since EVA film needs more than 1000 hours of test in 85°C/85%R.H condition (equal to at least about 42 days), in order to shorten the test time and accelerate the test speed, it is necessary to increase the environmental stress (temperature & humidity & pressure) and speed up the test process in the condition of unsaturated humidity (85%R.H).

Test conditions: 110°C/85%R.H./264h

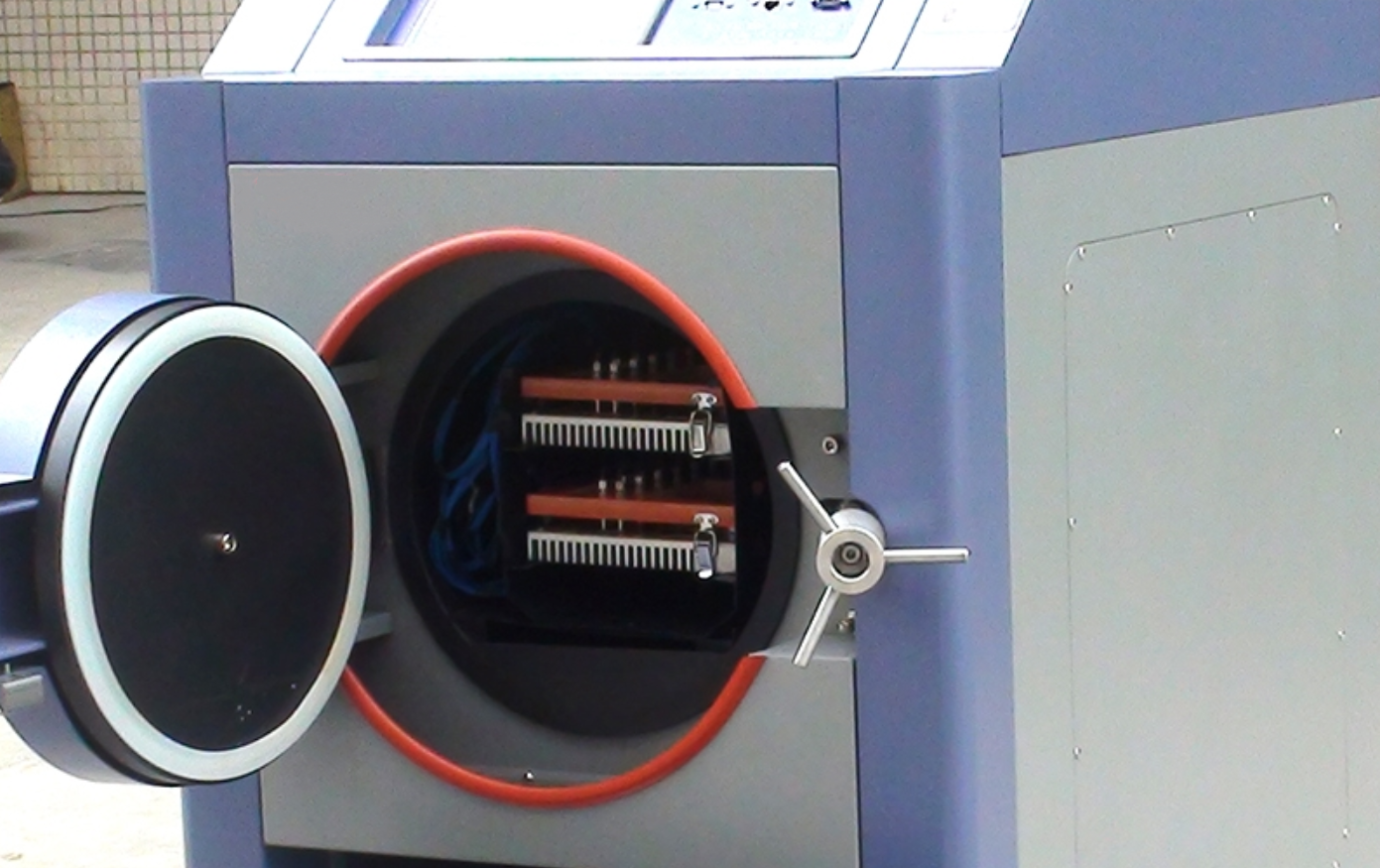

EVA-PCT Chamber:

Objective: The PCT test of EVA is to increase the environmental stress (temperature & humidity) and expose EVA to wetting vapor pressure of more than one atmosphere, so as to evaluate the sealing effect of EVA and the moisture absorption status of EVA

Test condition: 121°C/100%R.H.

Test time: 80h(COVEME)/ 200h