Labtech supplied IPX1~6 Water Test Chamber to Uzbekistan

Labtech successfully delivered a full-featured IP Water Test Chamber to a user in Uzbekistan, integrated IPX1, IPX2, IPX3, IPX4, IPX5 & IPX6 waterproof test in one chamber.

The system includes:

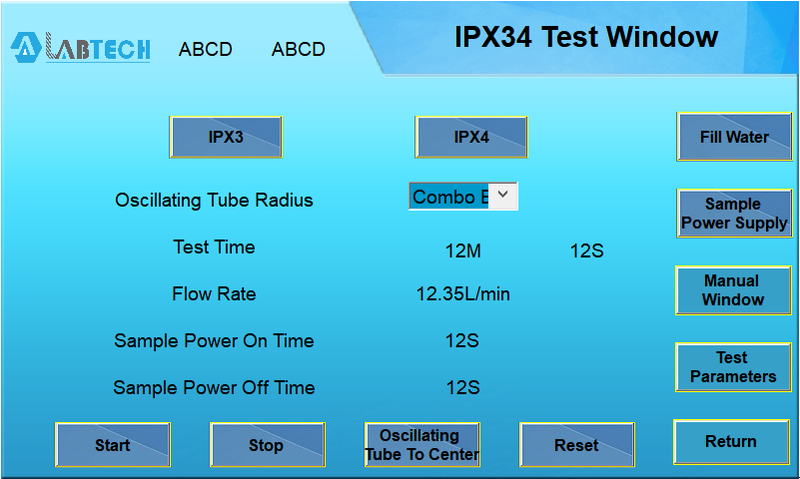

PLC Control System: Control the test by IP codes and display parameters with time, test cycle, water flow rate…

Turntable: Automatically rotates the sample to ensure uniform water exposure.

Drip Device: Facilitates IPX1 and IPX2 Water Drip tests with adjustable flow and timing.

Oscillating Tube: Delivers IPX3 and IPX4 spray patterns to mimic rain and angled water contact.

Jet Nozzle System: Capable of performing IPX5 and IPX6 Water Test using high-pressure jets at defined flow rates and angles.

Water tank: Collect and store water for cyclic use.

This export marked a significant step in Labtech’s global expansion, offering precise, durable, and user-friendly testing solutions. The user reported the equipment to be robust, compliant, and easy to operate, ensuring reliable IP testing performance.

Let’s know how Waterproof Test Chambers support industry compliance and product safety?

Electronics exposed to water without proper testing risk short circuits and failure. IP testing with a drip and spray chamber ensures long-term waterproof reliability.

IP Water Test Chambers simulate real-world water exposure, helping manufacturers meet IPX1–IPX6 standards. These tests use rotating turntables, oscillating tubes, and nozzles to deliver controlled water sprays and drips.

Which standards can IP Water Test Chamber comply with?

Water Test Chambers are specifically engineered to comply with international ingress protection standards. These standards define the levels of sealing effectiveness against water intrusion and are vital for product safety and certification:

IEC 60529: The primary international standard for IP code compliance, covering IPX1 to IPX6 testing protocols.

ISO 20653: Used in the automotive industry, outlining IP requirements under harsher conditions.

GB/T 4208: China's national adaptation of IEC 60529, widely used in domestic product validation.

The IPX1–IPX2 tests simulate vertical water drips, IPX3–IPX4 use oscillating tubes and spray nozzles to simulate water sprays at varying angles, while IPX5–IPX6 require powerful jet nozzles to test resistance against pressurized water. Labtech’s IP test chambers are designed to support all these configurations with precise control.

Which industries can waterproof test chambers be applied?

Waterproof testing is critical across multiple sectors where electronics and enclosures face moisture exposure:

Consumer Electronics: Phones, cameras, and wearable devices undergo IPX34 Water Spray Test and IPX12 Water Drip to ensure waterproof durability.

Automotive: Headlights, sensors, and control units must comply with IPX56 Water Test requirements to withstand rain and car washes.

Appliances: Washing machines, dishwashers, and outdoor equipment are tested for their resistance to water jets and drips.

LED Lighting: Outdoor lighting systems are tested with oscillating tubes and jet nozzles for ingress protection under various rainfall conditions.

Defense and Aerospace: Equipment needs to maintain performance in extreme environments, making IP testing essential.

These industries rely on waterproof test chambers to ensure safety, longevity, and certification compliance under real-world usage scenarios.

In summary, Labtech’s IP Water Test Chambers deliver reliable and standardized waterproof testing for critical product certification and durability.