Why Is Cone Calorimeter Essential for Flammability Testing?

Flammable materials pose serious safety risks - uncontrolled fires can lead to catastrophic damage. Accurate flammability testing is crucial to mitigate these risks. The Cone Calorimeter provides precise, standardized assessments of material combustion behaviors, ensuring safety and compliance.

Cone Calorimeter is a pivotal instrument in fire safety testing, measuring key parameters like heat release rate (HRR), time to ignition, and smoke production. Its adherence to international standards ensures reliable and comparable results across various industries.

Which standards can Cone Calorimeter comply with?

Cone Calorimeter is designed to meet several international fire testing standards, ensuring its applicability across various regulatory frameworks. Key standards include:

ISO 5660-1, ASTM E1354, BS 476 Part 15, ASTM E1474, ASTM E1740, ASTM F1550, ASTM D6113…

Compliance with these standards ensures that the Cone Calorimeter provides reliable and standardized data for fire safety assessments.

How many working modules does the Cone Calorimeter contain?

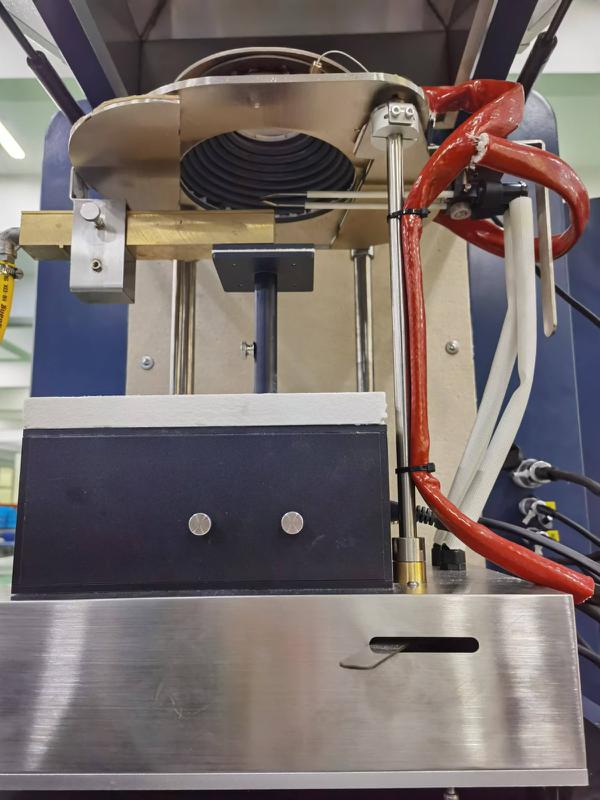

Cone Calorimeter comprises several integrated modules, each serving a specific function in the testing process:

- Radiant Cone Heater: Delivers a controlled heat flux, typically set at 50±0.5 kW/m², to the test specimen.

- Load Cell: Measures the mass loss of the specimen during combustion, providing data on burning rate.

- Exhaust System: Collects combustion gases and directs them to analyzers for assessing smoke and gas production.

- Gas Analyzers: Determine concentrations of oxygen, carbon monoxide, and carbon dioxide in the exhaust gases.

- Smoke Measurement System: Evaluates the optical density of smoke produced during combustion.

- Data Acquisition System: Records and processes data from various sensors, enabling comprehensive analysis of combustion behavior.

These modules work in unison to provide a detailed profile of a material's flammability characteristics.

What are the measurements of a Cone Calorimeter?

Cone Calorimeter measures several critical parameters that characterize the combustion behavior of materials:

• Heat Release Rate (HRR): The rate at which heat is released by the burning specimen, expressed in kW/m².

• Total Heat Release (THR): The total amount of heat released during the combustion process.

• Time to Ignition (TTI): The duration from the start of the test to the ignition of the specimen.

• Mass Loss Rate (MLR): The rate at which the specimen loses mass during combustion.

• Smoke Production Rate: The amount of smoke generated, measured using optical density.

• Gas Concentrations: Levels of oxygen, carbon monoxide, and carbon dioxide in the exhaust gases.

These measurements provide a comprehensive understanding of a material's fire performance, aiding in safety assessments and material development.

How does the Cone Calorimeter perform calculations?

Cone Calorimeter calculates the Heat Release Rate (HRR) using the principle of oxygen consumption calorimetry. This method is based on the observation that the amount of heat released during combustion is directly proportional to the amount of oxygen consumed. The calculation involves:

• Measuring Oxygen Concentration: Determining the difference in oxygen levels between incoming and outgoing air streams.

• Assessing Gas Flow Rate: Measuring the volume of gases passing through the system.

• Applying Huggett's Constant: Utilizing a constant value that relates oxygen consumption to heat release, typically 13.1 MJ/kg of oxygen.

The formula used is: HRR = (ΔO₂ × Flow Rate × Heat of Combustion) / Sample Area This calculation provides accurate and reliable data on the energy released during combustion.

Which gas sources are needed for a Cone Calorimeter?

The primary gas required for operating a Cone Calorimeter is methane with a purity greater than 99.5%. Methane serves as the fuel for the calibration burner, ensuring accurate heat flux delivery from the radiant cone heater. The use of high-purity methane is crucial for maintaining consistency and reliability in test results.

Additionally, the system requires a supply of N2 and Span gas (CO < 1% / CO2 < 10% / the remaining is N2 ) for gas analyzers. Proper gas supply and management are essential for the accurate functioning of the Cone Calorimeter.

In summary, Cone Calorimeter is an indispensable tool in fire safety testing, providing standardized and precise measurements of material flammability.