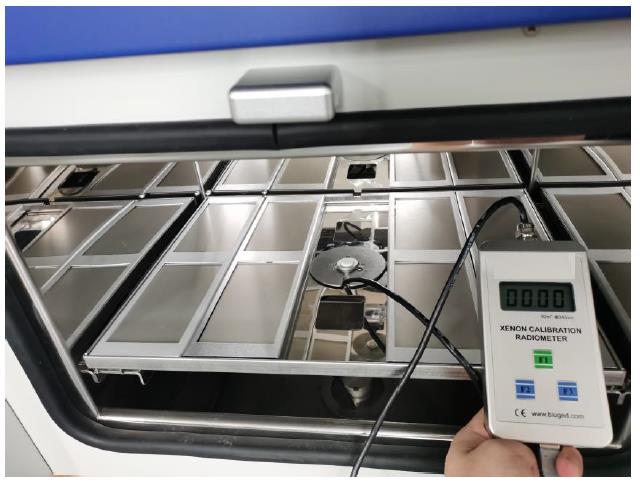

Xenon Test Chamber ISO 4892-2 for Testing Anodized Aluminum Parts and Plastic Components

Application:

Labtech Instrument supplied Xenon Test Chamber to customer in Iceland for testing anodized aluminum parts and plastic components to the standard ISO 4892-1/4892-2. The chamber can 9pcs test samples in size 70*140*10mm and weight 700g, and irregular samples in dimensions 20 width x 30 depth x 200 height (mm) can be tested also.

Xenon lamp is used by Xenon Test Chamber can reappear the full spectrum sunlight realistically, including ultraviolet rays, visible light and infrared rays. The life time of xenon lamp is approx. 1,500 hours, an extra lamp for long time test is essential.

Water spray can effectively simulate heat shock or mechanical erosion caused by dramatic temperature changes or rain. Xenon Test Chamber spray system design with 2 nozzles which are located the central top of cabinet, each side has 1 piece. Spray system can run a few minutes and then shut down. This transitory water spray can cool the samples quickly, creating heat shock conditions. Furthermore, xenon test chamber can run the water spray during either light or dark cycle. Pure water system is option also.

Transportation:

Xenon Test Chamber and Pure Water System were packed in 2pcs plywood cased, which were shipped by sea to ROTTERDAM first, then transship to REYKJAVIK, Iceland. The packages have 2CBM and 300kgs.

It takes about 3 weeks from Shenzhen China to REYKJAVIK, Iceland by sea.

Installation & Commissioning:

Xenon Test Chamber arrived REYKJAVIK, Iceland in July, 2023. The customer finished the installation and commissioning with instructions of user manual and operation video