Application:

The corrosion of metal materials with or without protection is affected by many environmental factors, which mainly depend on the type of metal materials and environment. It is not possible to design laboratory accelerated corrosion laboratories include all environmental factors that influence corrosion resistance, so design laboratory tests that simulate the factors that play a major role in corrosion of metallic materials.

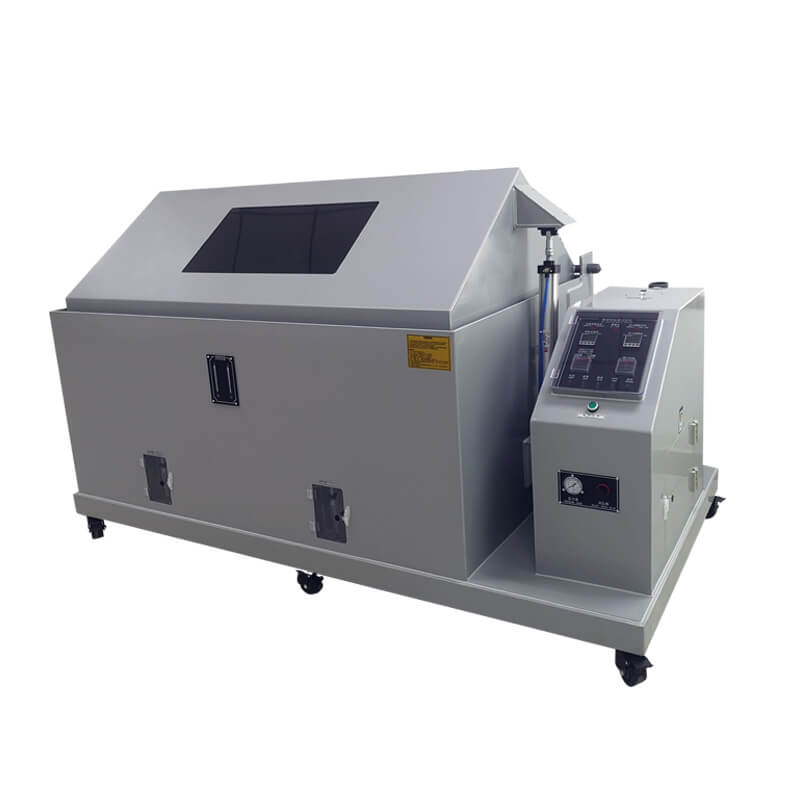

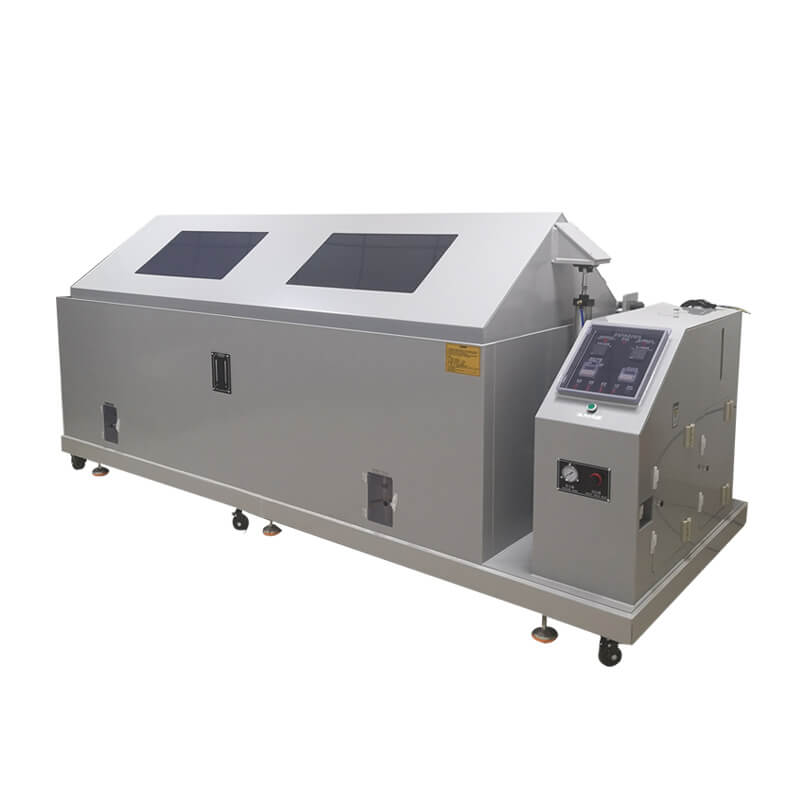

Salt Spray Chamber is designed to simulate and increase the environmental impact on metallic materials exposed to salt-contaminated outdoor atmospheres that can accelerate corrosion.

Corrosion test (salt spray at 35˚C continuously, which refer to test standard ASTM B117) is one way to simulate corrosion in our labtorary. Salt Spray Chamber includes a test method for cyclic exposure of samples to salt spray, dry, humid and hot environments.

Salt Corrosion test is a comparative test, the results which cannot predict the long-term corrosion resistance of the same metal material used under such environmental conditions.

However, this method can still provide valuable information about the properties of materials exposed to salt pollution conditions similar to the test conditions

Salt spray exposures Continuously is widely specified for testing coatings and components for corrosion resistance.

The major tests are performed to particular test standard such as BS 3900 F4 , ASTM B117 and so on.

Compared with traditional accelerated corrosion tests, such as neutral salt spray test (NSS), Acetate spray test (AASS), and Copper accelerated acetate spray test (CASS), Salt Spray Chamber has the greatest advantage that it can reproduce the corrosion in outdoor salt pollution environment better.

Specification:

|

Inner size

(L×W×H) mm

|

600×400×450

|

900×600×500

|

1200×1000×500

|

|

External size

(L×W×H)mm

|

1070×600×1180

|

1410×880×1280

|

1900×1300×1400

|

|

Equipment material

|

Both internal and external material are imported PVC plastic; the cover is transparent PVC

|

|

Temp. range

|

35°C~55°C

|

|

Temp. fluctuations

|

≤±0.5°C

|

|

Temp. uniformity

|

≤±2°C

|

|

Temp. precision

|

±1°C

|

|

Test chamber temp.

|

NSS ACSS 35±1°C CASS:50±1°C

|

|

Saturated air barrel temp.

|

NSS ACSS 47±1°C CASS 63±1°C

|

|

Brine temp.

|

35°C±1°C

|

|

Spray quantity

|

1.0~2.0 ml / 80cm2 / hr

|

|

PH

|

NSS ACSS6.5~7.2 CASS 3.0~3.2

|

|

Lab volume

|

108L

|

270L

|

600L

|

|

Brine tank capacity

|

15L

|

25L

|

40L

|

|

Power

|

1AC220V,10A

|

1AC220V,15A

|

AC 1,220V,30A

|

|

Multiple safety protection devices

|

Water shortage/ over temperature/ phase protection

|

|

Standard accessories

|

Test salt, measure bucket, tool 1 set

|