Application:

The corrosion of metal materials with or without protection is affected by many environmental factors, which mainly depend on the type of metal materials and environment. It is not possible to design laboratory accelerated corrosion laboratories include all environmental factors that influence corrosion resistance, so design laboratory tests that simulate the factors that play a major role in corrosion of metallic materials.

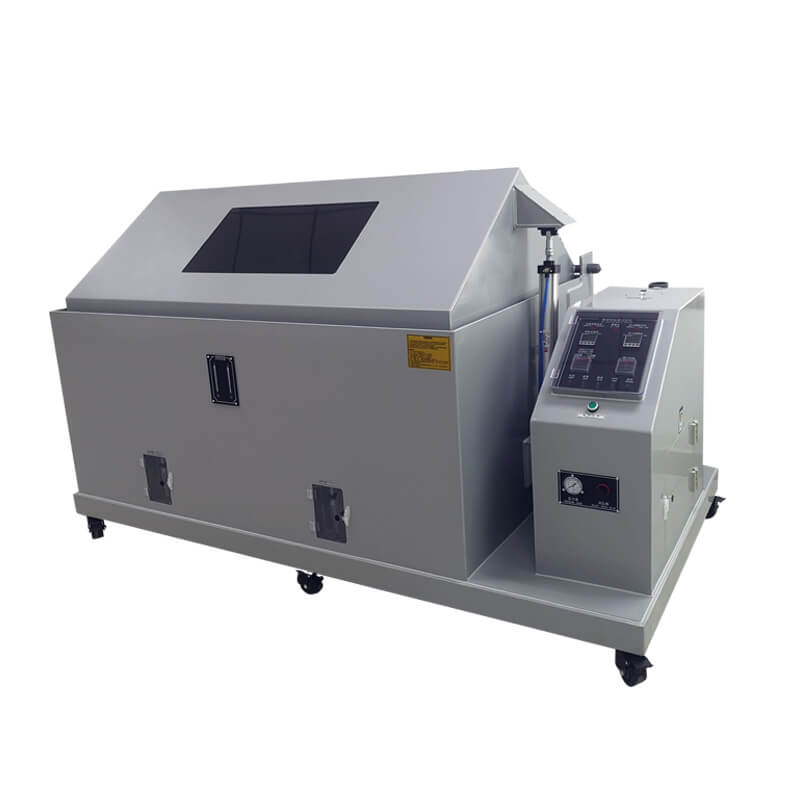

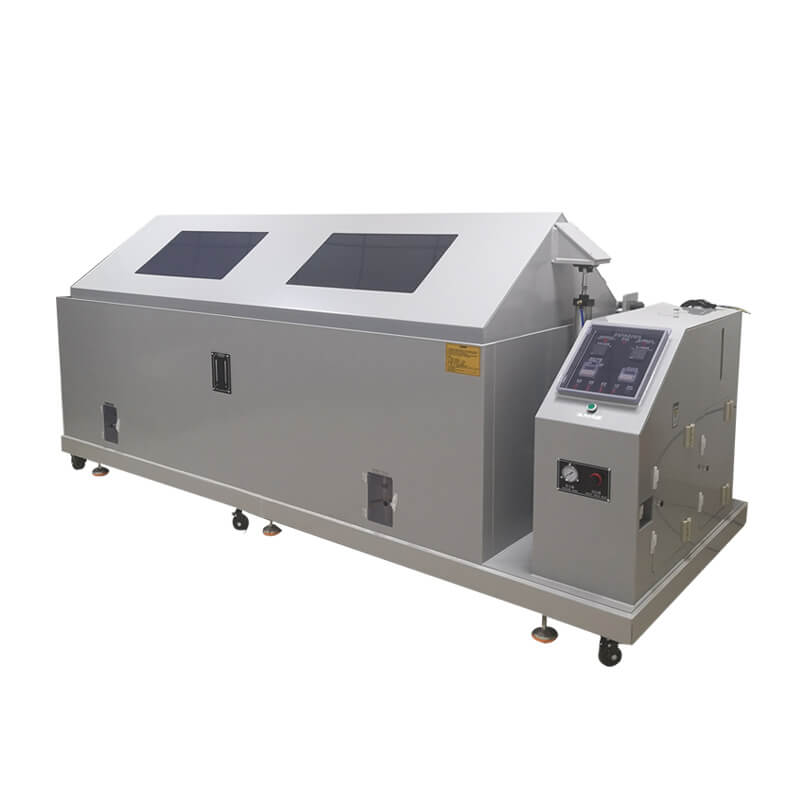

Walk-in Salt Spray Chamber is designed to simulate and increase the environmental impact on metallic materials exposed to salt-contaminated outdoor atmospheres that can accelerate corrosion.

Corrosion test (salt spray at 35˚C continuously, which refer to test standard ASTM B117) is one way to simulate corrosion in our labtorary. Salt Spray Chamber includes a test method for cyclic exposure of samples to salt spray, dry, humid and hot environments.

Walk-in Salt Corrosion test is a comparative test, the results which cannot predict the long-term corrosion resistance of the same metal material used under such environmental conditions.

However, this method can still provide valuable information about the properties of materials exposed to salt pollution conditions similar to the test conditions

Salt spray exposures Continuously is widely specified for testing coatings and components for corrosion resistance.

The major tests are performed to particular test standard such as IEC60068-2-11 , ASTM B117 and so on.

Compared with traditional accelerated corrosion tests, such as neutral salt spray test (NSS), Acetate spray test (AASS), and Copper accelerated acetate spray test (CASS), Salt Spray Chamber has the greatest advantage that it can reproduce the corrosion in outdoor salt pollution environment better.

Design Standards:

ASTM B117, IEC60068-2-11

Specification:

|

Internal dimension

(W*D*H)

|

1500*1600*1600mm (Customized)

|

|

External dimension

(W*D*H)

|

1700*2300*2300mm

|

|

Door structure

|

Single door with one observing window

One door size: W65cm*H150cm, two doors size: W130cm*H150cm

|

|

Temperature uniformity

|

≤±2℃

|

|

Temperature fluctuation

|

≤±0.5℃

|

|

Temperature range

|

(RT+10℃) to 80℃, nature air cooling

|

|

Temperature sensor

|

Pt100 Ohm A-Class

|

|

Controller

|

PLC Touch screen

|

|

Timing setting for test

|

1-999hr, adjustable

|

|

Heater

|

Heater for room: 2.5KW, 3 pcs, titanium alloy type

Heater for pressure barrel: 500W, stainless steel type

|

|

Equipment material

|

PP rigid plastic plate, thickness 10mm

|

|

Equipment structure

|

1. Spray tower: 4 groups

2. Spray systems: 4 groups

3. Demist systems: 1 group

|

|

Salt water filtration

|

Salt water filter near the suction tubes for easy operation

|

|

Salt fog collecting

|

Salt fog collector and fog measuring cylinder

|

|

Spraying method

|

Continuous and periodic spray type

|

|

Test chamber temperature

|

Salt Spray Method (NSS ACSS)35±1℃

Corrosion-resistant Testing Method (CASS) 50±1℃

|

|

Saturated air barrel temperature

|

Salt Spray Method (NSS ACSS)47±1℃

Corrosion-resistant Testing Method (CASS) 63±1℃

|

|

Brine temperature

|

35℃±1℃

|

|

Fog collection rate

|

1.0~2.0 ml / 80cm2 / hr

|

|

PH value

|

Salt Spray Method (NSS ACSS6.5~7.2)

Corrosion-resistant Testing Method(CASS)3.0~3.2

|

|

Salt solution tank capacity

|

100L

|

|

Water supply

|

Test chamber with tap water automatic supply, no need to add by manual

|

|

Multiple safety protection devices

|

Current discharge protection, over pressure protection, over temperature protection, over load fuse protection

|

|

Accessories

|

1. Nacl: 6 bottles

2. Glacial acetic acid: 1 bottle

3. Cucl: 1 bottle

4. PH test trips: 1 box

5. Salt solution barrel: one pc with 5L

6. Demist tube: 3m

7. Spray Nozzle: 4 pieces

|

Advantages:

1.Special design can be made according to different requirements

2.Electronic temperature sensor, high precision, low maintenance

3.Add water manually & automatically should be determined by customer installation site, easy to use

4.The control chamber is independent from the test chamber, and the connection is controlled through the damper in the middle. The structure is perfect and the maintenance is more convenient

5.Energy saving design, separate control according to different tests

6.Salt spray neutral test, corrosion resistance test, dry test, wet test, static test can be done alone, or salt spray, dry wet, static mixed test, automatic control

7.Automatic cycle spray, continuous spray, timing spray

8.Automatic cycle test of salt spray, humid heat and drying can be realized without moving products, which is easy to use

9.Long-term stable operation