| 1. Product Name | Walk-in Environmental Chamber |

| 1.1 Model | R-WTH series |

| 1.2 Internal volume | 2.0*1.5*2.0m, 3.0*1.8*2.0m, Can be customized with any size |

| 2. Performance |

| 2.1 Environmental condition | Temperature: +25℃, Relative humidity≤85%, without test specimen |

| 2.2 Temperature range | -70°C to +200 °C as per customized requirements |

| 2.3 Temperature fluctuation | ±0.5℃ |

| 2.4 Temperature uniformity | ±2℃ |

| 2.5 Humidity range | 20%-98% RH (5% and 10% for optional) |

| 2.6 Humidity fluctuation | ≤±3%R.H. |

| 2.7 Humidity uniformity | ≤±3%R.H. |

| 3. Structure |

| 3.1 Frame material | Chamber external material: steel plate with electrostatic spraying surface treatment Chamber internal material: SUS304 Chamber insulation material: high density rigid polyurethane foam + fiberglass Door insulation material: high density rigid Polyurethane foam |

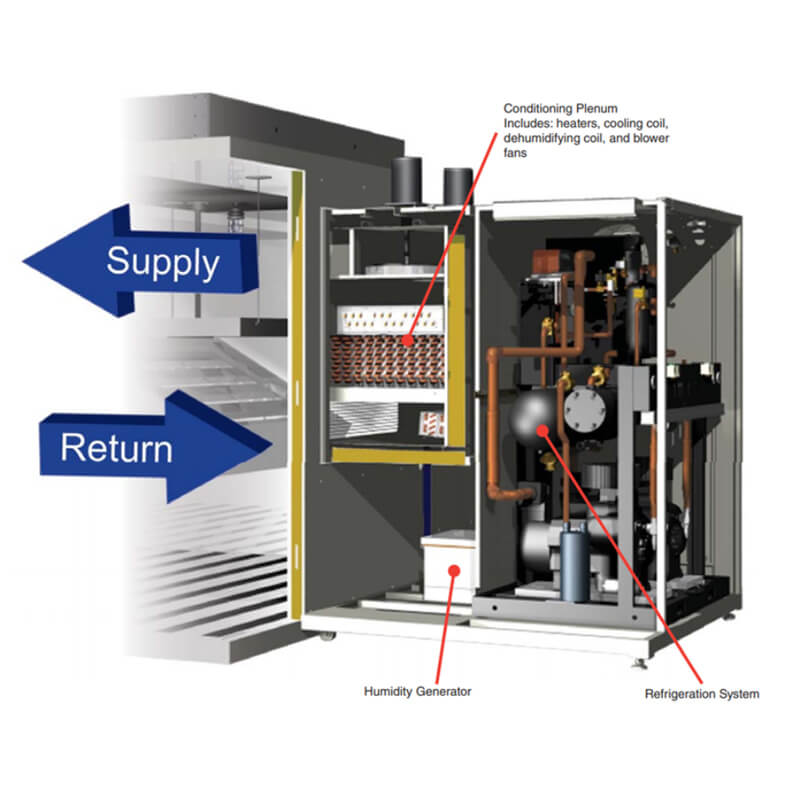

| 3.2 Air conditioning channel | Centrifugal fans Heater, humidifier, dehumidifier, evaporator, water supply and drainage hole, temperature sensor |

| 3.3 Standard configuration | Two observing windows Special door lock Door hinge: SUS #304 Lamp on the top of chamber:2 pcs lamps |

| 3.4 Door | Double door Observing windows , lamp Door and window frame with anti-condensation electric heating device |

| 3.5 Control panel | Controller, over temperature protection setting device |

| 3.6 Machine room | Refrigerating unit, water pan, drain hole |

| 3.7 Power distribution | Power distribution board, exhaust fan |

| 3.8 Heater | Heating system: fin- type stainless steel heater |

| 3.9 Humidifier | Shallow trough boiler type humidification system |

| 3.10 Dehumidifier | Special humidification system for low humidity requirement |

| 3.11 Power wires hole and water drain hole | In the bottom of chamber |

| 4. Refrigerating system |

| 4.1 Cooling way | Air cool or water cool |

| 4.2 Compressor | Germany brand Bock |

| 4.3 Evaporator | Fin-type multi-stage automatic load capacity adjustment |

| 4.4 Condenser | Fin type air cool condenser |

| 4.5 Expansion system | Capacity-controlled refrigeration system (capillaries) |

| 4.6 Plate heat exchanger | Stainless steel brazing plate heat exchanger. |

| 4.7 Refrigerator control way | Automatic adjust operation condition as per test condition Evaporation pressure regulating valve Compressor return air cooling loop |

| 4.8 Refrigerant | R404a |

| 5. Electrical control system |

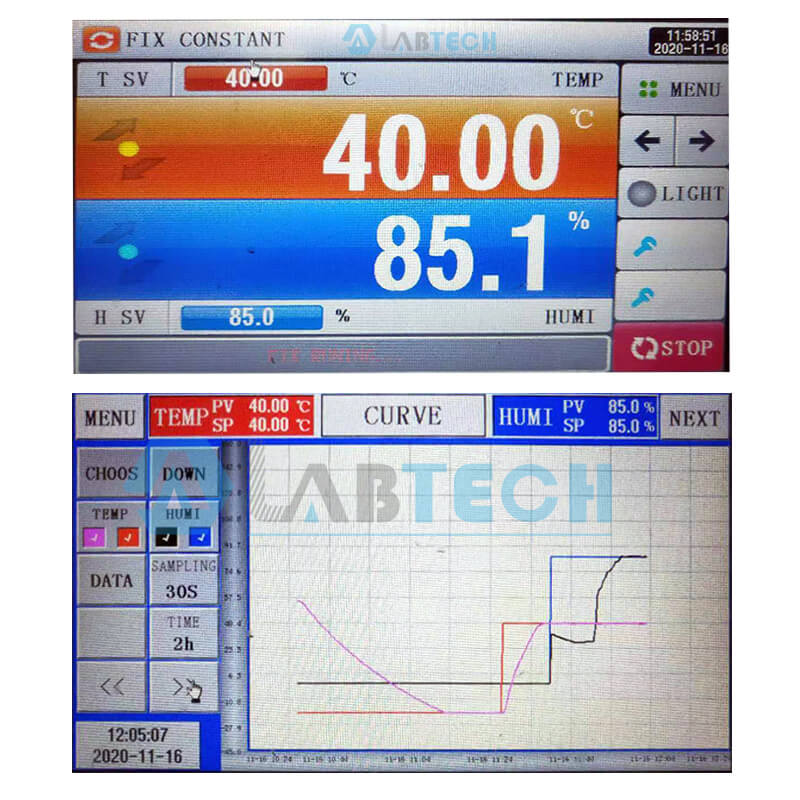

| 5.1 Control system | PLC touch screen controller |

| 5.2 Controller specifications | Accuracy: temperature ±0.1℃ + 1digit, humidity ±1 %RH + 1digit; Resolution: temperature 0.1℃, humidity ±0.1 %RH; With upper and lower limits of standby and alarm functions; Temperature humidity input signal wet and dry bulb PT100 x 2; 9 groups P.I.D control parameter setting, P.I.D auto calculation; Wet and dry bulb automatic correction; |

| 5.3 Display functions | Color touch screen Temp. SV and PV display directly Display current segment number and left time and cycle times Running total time Temp. set value and curve display, real-time curve display With separate program editing screen; each page can input at least 5 segments temperature and time English interface; fault reminder display Screen with backlight adjustment; timing screen display protection function, TIMER or manual shutdown setting |

| 5.4 Program segment capacity and control functions | Program: Max. 120 pattern Capacity: 12000 segments Repeat command execution: each one can reach 3200times Functions has editable, delete, insert etc Time setting for segment: 0~99Hour59Min Programmable sequence control module unit x2 groups Power off program memory, automatically start and continue to execute the program function after the resumption of power RS-232 / USB connecting Real-time curve display Automatic adjustment for freezing function; reserved start and shutdown function Date, time editable, buttons and screen lock function |

| 6. Safety protection device |

| 6.1 Refrigerating system | Compressor overvoltage, overheat and overload protection; Cooling fan overheat protection |

| 6.2 Chamber | Over temperature protection; Air conditioning channel extreme over temperature protection; Fan and motor over heat protection |

| 6.3 Other | Main power phase sequence and phase-break protection; Earth leakage protection; Heat, wet, dry, burn protection; Overload and short circuit protection; Power-off protection |

| 7. Other configuration |

| 7.1 Specimen power supply control terminal | Relay contact control, AC220V, ≤2A (When in normal operation, the contact closes; when the chamber stops or fails, the contact is off-contact) |

| 7.2 Main power electric leakage breaker | AC380V, 50Hz, power will be changed as per required change rate |

| 7.3 Power wires | Five-core (three-phase four-wire + protective ground wire) One cable with length 3m |

| 7.4 Test hole | Hole diameter can be φ50mm, φ80mm, φ100mm, φ120mm for optional |

| 7.5 USB port | Test curves and test data can be downloaded and saved by excel and JPG |

| 8. Shipment: chamber as a whole one for shipment or split-type |

| 9. Environmental conditions |

| 9.1 Installation place | -Room with smooth ground and good ventilation, no heavy vibration around the equipment -No strong electromagnetic field around -No inflammable, explosive, corrosive articles and dust -With enough space for operation and maintenance (as image below) A, >80cm B, > 80cm C, >120cm |

| 9.2 Environmental conditions | -Environment temperature: 5 ~ 30 ℃, relative humidity≤85% RH; -The installation site must be flat and vibration-free; -The installation site shall not be directly exposed to sunlight and shall maintain indoor air circulation; -The equipment installation site shall be cleaned and shall not be installed in dusty places or dust outlets |

| 9.3 Power supply | -AC380 V, three-phase four-wire + protective ground wire -Power: change as per required change rate -Voltage: AC(380±10%)V; frequency: (50±0.5)Hz -Protective ground wire resistance< 4Ω User needs to provide required independent air switch for this chamber. |